Accommodation Containers

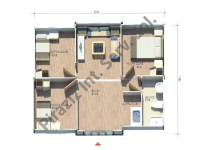

Containers manufactured by means of Unwelded Structure Technology(UST) can be manufactured as single, two or three-storey combinations depending on requirements. Standard products’ surface coatings, in accordance with customers’ choice can be of painted galvanized steel sheet or A-1 class fire resistant HEKIMBOARD branded boards produced by the fibercement technology and Hekim Sandwich Panels produced by one of Hekim Holding Companies.

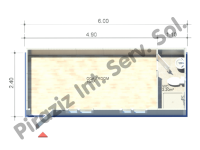

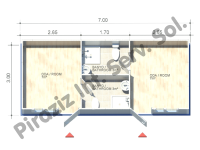

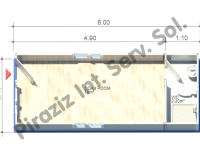

We can create custom structures to your requirements beside the standard dimensions 3,00×7,00 m and 2,40×6,00 m. Depending on the intended use, containers can be manufactured according to Hekim Panel- Hekim Classical type as in the form of demountable or factory erected so called as monoblock.

Transport and unloading of issues to be considered during the

- Container has to be lifted or lowered from 2x2cm eyebolts at corners by means of Crane,

- Ropes have to be cross-connected.Make sure that lenght of ropes are equal and the angle of the horizantal is not less than 200 (36% slope),

- Hook has to be in balance and shifted towards heavy side during lifting process.

- To use the container longer, make sure that the ground to be placed on is levelled, if possible concrete or to be placed on skids by the lenght of short edge at an interval of max. 2,5m.

- Make sure that the ground that the container is placed is levelled in order to avoid possible problems in door and window joineries.

- Make sure that container’s main chasis is fully supported on the ground.

Intended Use

- Office

- Accomodation unit

- Dormitory

- Showroom and sales office

- Site Camp

- School

- Hospitals

- Military camp

- Restaurant

- Emergency establishment

- Dininghall & kitchen

- WC&Shower unit

- Cold Room

- Foldable Container

- Nested Unit

Factory Erected-Monoblock

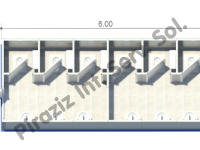

It is the type that container’s production and assembly is completed at factory made ready for despatch. We can create custom structures to your requirements beside the standard dimensions 3,00×7,00 m and 2,40×6,00 m. Monoblock containers are available in 2 different system.

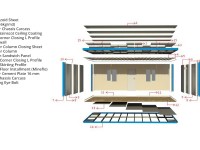

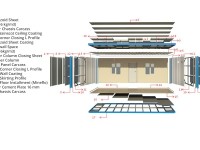

Sandwich Panel Container (Hekim Panel):

Sandwich panels produced by one of Hekim Holding companies are used in this system. It is possible to create different wall coating options such as steel sheet+ Steel sheet, sheet + pet (polyethylene terepthalate).EPS or rockwool insulated container options stand out with high insulation values.

Hekim Classical Container:

High standard galvanised structural steel is used for containers designed according to light weight and unwelded steel structure technology and solutions.PVC lapping or fibercement board is used as an interior surface cladding for containers which has galvanized trapezoidal steel sheet as an exterior cladding.

Demountable

In this production system, container’s wall components, bottom and top chasis are not assembled at factory. All the items are packed specially and got ready for despatch. Short period of production, easy assembly and transportation are among the advanteges of the system.While only 2 pcs of monoblock containers are shipped in one truck, with this system 8-10 pcs of 2,4*6m empty volume containers can be shipped in one truck. Available in three different demountable container production system. Supervisor and / or the assembly team is available.

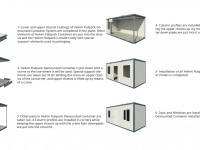

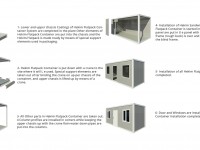

Hekim FlatPack-Plus Container:

We aim to decrease the cost of our customers ensuring maximum efficiency at the stage of transportation (sea, air, land) with the custom packaging and unwelded structure technology used containers. Demountable Hekim Panel Containers can be easily and quickly unassembled and become ready to used at site.

Hekim FlatPack Container:

This system in which in some particular details, welding is used, offers advantage from the transport, fast production and assembly point of view. Demountable Hekim Panel Containers can be easily and quickly anssembled and become ready to used at site.

Hekim Profile System Container:

In this system Hekim Classical Container’s frames are dispatched demountable as in profile system. Insulation material, electrical and plumbing supplies, doors, windows, etc. are packaged separately. All the assembly stages are performed at construction site. Supervisor and / or the installation team is available.